CASES

Cold heading oil filtration project in Shandong fastener industry

Type:

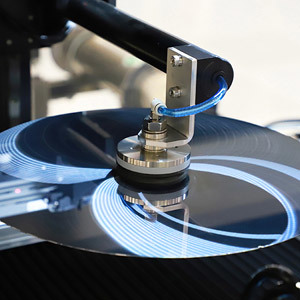

Cold Heading Oil Filtration and Slag Removal

Industry:

Fastener Manufacturing and Processing

Customer Background

Shandong Fastener Industry Cold Heading Oil Filtration Project is the third largest fastener enterprise in China, established in 2015. The company's main business products such as fasteners, auto parts, metal products and their processing are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemicals, military equipment, aerospace and other fields.

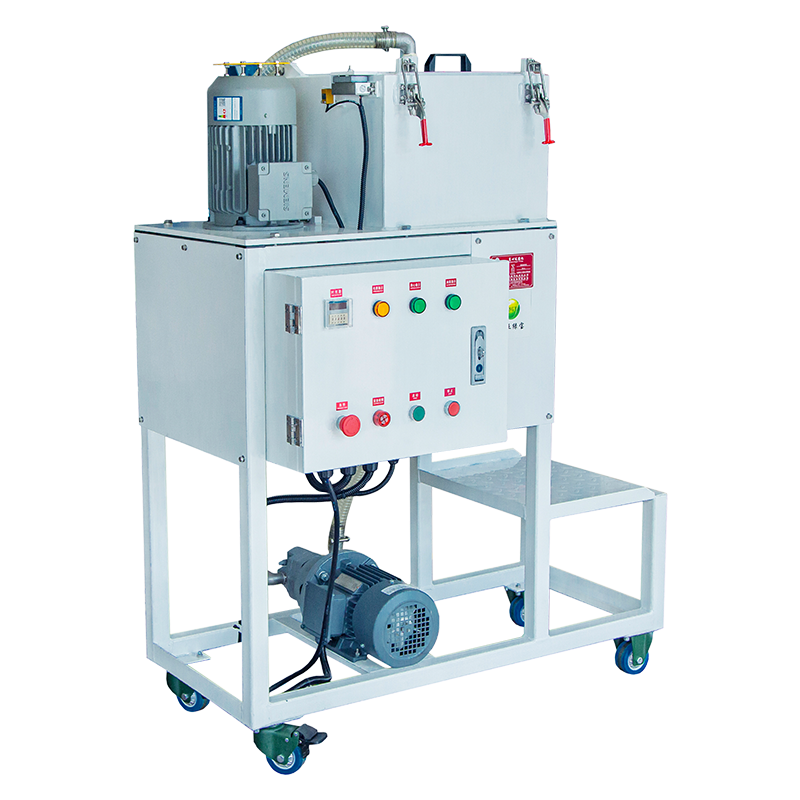

Project Introduction

Customer pain point:

During the cold heading process, the wire drawing powder on the wire falls into the cold heading oil. As time goes by, the cold heading oil is seriously polluted, causing the failure rate of the cold heading machine equipment to increase. The previous solution was that the oil needs to be replaced regularly, so the replacement cost of the oil in the production cost is relatively high.

Solution:

After adding our company's fully automatic centrifugal filter, the service life of the oil is extended; the equipment failure rate is reduced. After benefit analysis, it has been recommended by the industry and friends in the industry.

Customer Testimonials

Customer evaluation: After using the centrifugal filter, there is basically no need to clean the cold forging oil residue, only the barrel needs to be changed regularly. The production efficiency is improved, which is very suitable for the optimization process of cold forging oil disposal.

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy