APPLICATIONS

Fastener Processing

Fastener processing

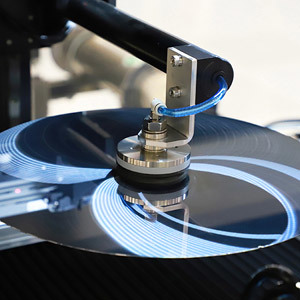

Fasteners are basic parts widely used in industry, with various varieties and specifications, and high degree of standardization and serialization. Centrifugal filters are widely used in process improvements such as cold heading, thread rolling, and quenching in the fastener industry.

Industry Introduction

Source:

It mainly appears in cold heading oil in the cold heading process of fastener production, thread rolling oil, quenching oil, tapping oil, etc. in workpiece processing.

Oil composition:

It is mainly the original processing fluid and heavy metal particles, dust, moisture, air and other impurities generated after long-term use.

Process impact:

The processing fluid becomes turbid and deteriorates after long-term contamination, and produces microorganisms; it will make the oil black and smelly, reduce the service life of the oil and the precision quality of the workpiece, and make the production environment worse.

Usage effect:

It can greatly reduce the phosphoric acid powder, iron pins, oil sludge, etc. in the forming oil and maintain a certain viscosity value of the lubricating oil, extend the service life of the forming oil by 3-5 times, and reduce the wear of the oil pump, mold and machine moving parts.

Product Recommendations

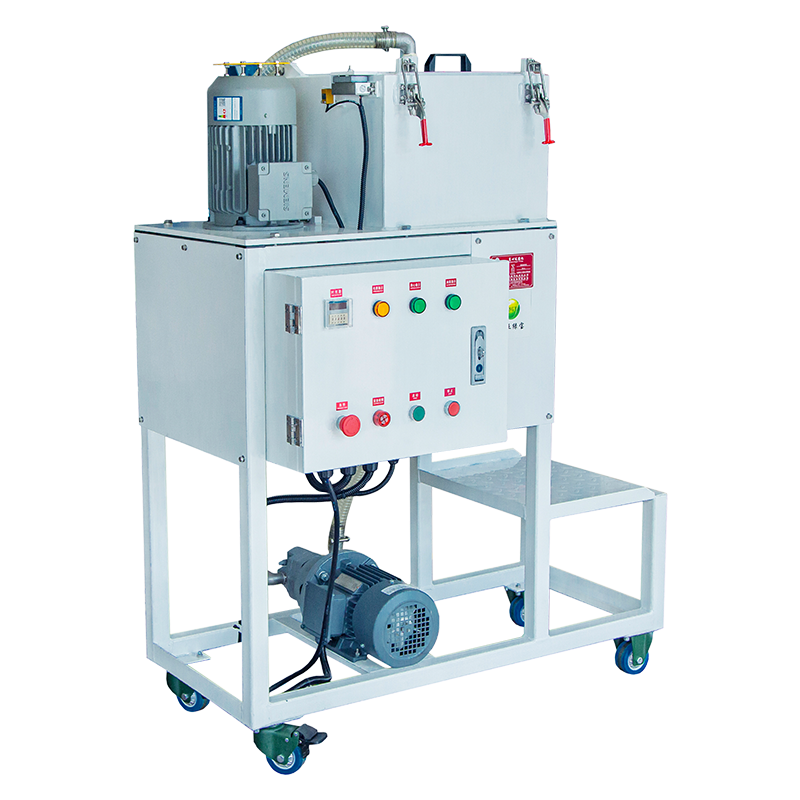

Fully automatic slag removal centrifugal filter

1. Extend the service life of oil/liquid by 3-5 times

2. The equipment occupies a small area and can be operated in a mobile manner

3. Improve product quality and reduce product wear

4. Reduce the maintenance cost of production equipment and reduce the generation of waste oil

5. Optimize production process and improve working environment

6. No filter screen or filter element replacement, no consumables

7. Fully automatic control, automatic slag removal, no need for personnel on duty

8. Separate impurities larger than 5μm in oil

9. The oil content of sludge is low and no de-oiling treatment is required

10. Frequency conversion design, the speed can be freely adjusted to change the centrifugal force G value

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy