CASES

Zhejiang Steel Pipe Processing Rolling Mill Oil Filtration Project

Type:

Rolling Mill Oil Centrifugal Filtration

Industry:

Steel Pipe Processing Industry

Customer Background

Zhejiang Steel Pipe Processing and Rolling Mill Oil Filtration Project Management: Stainless steel products, pipe fittings, flanges, electromechanical products, metal products, fasteners, mechanical equipment and accessories, leather production, processing, sales. In the production process of stainless steel precision seamless steel pipe cold rolling process, 20 cold rolling mills were planned in the new workshop, and there were a lot of cold rolling oil filtration problems.

Project Introduction

Customer pain points:

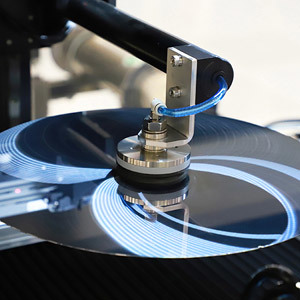

After the rolling mill oil has been used for a long time, there are too many impurities in the oil, the surface of the rolled steel pipe will be relatively dirty, and the rolling mill oil taken away by the inner and outer holes of the steel pipe will also increase. The subsequent cleaning process is also difficult to clean. The centrifuge can filter out most of the impurities in the oil, improve the cleanliness of the inner and outer holes of the steel pipe, reduce oil loss, and reduce the difficulty of subsequent cleaning.

Solution:

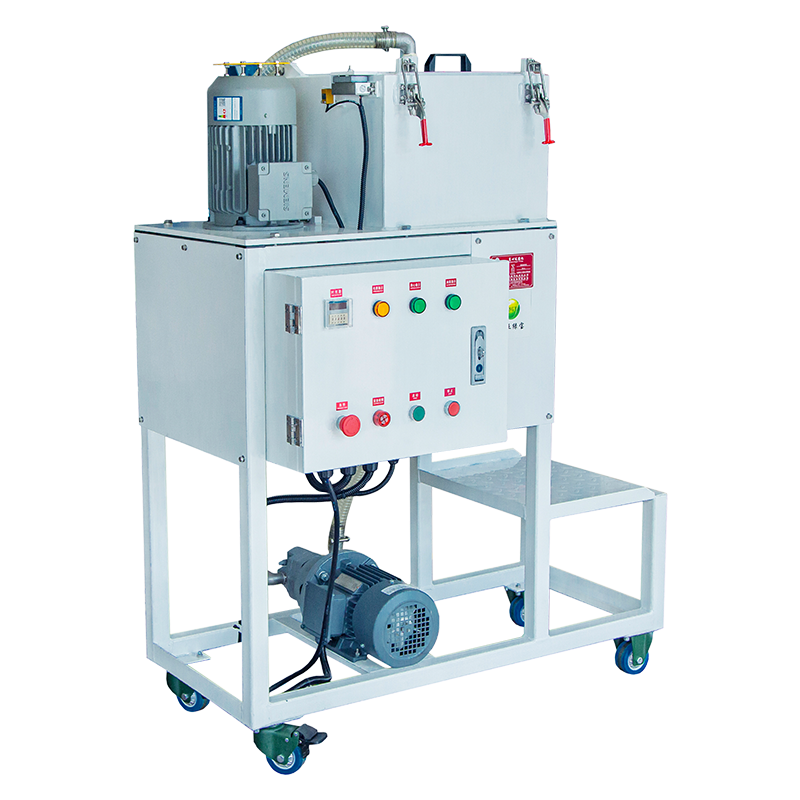

With the FY-1500 fully automatic centrifuge, the cold rolling oil is filtered for each cold rolling mill in turn through mobile filtration, and the effect of producing a large amount of sludge is very obvious. The surface of the steel pipe has also become significantly smoother.

Customer Testimonials

Customer evaluation: Very satisfied with the filtering effect. A large amount of metal sludge was centrifuged out and the viscosity of the rolling mill oil was reduced.

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy