CASES

Guangdong 3C Industry Glass Grinding Liquid Centrifugal Slag Discharge Project

Type:

Glass Grinding Fluid Centrifugal Slag Removal

Industry:

3C Industry

Customer Background

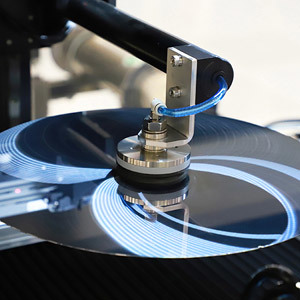

The client of the Guangdong Glass Grinding Liquid Centrifugal Project is a company that specializes in the development, production and sales of capacitive touch, micro camera modules, integrated touch modules, fingerprint recognition modules, precision glass components, magic glass, four-corner full uniform motors and other products. Its camera module products are widely used in mobile phones, tablet computers, MP3, MP4, toys, automobiles, image scanners, security monitoring and medical equipment, etc.

Project Introduction

Customer pain points:

The customer's grinder and cutter produce a large amount of glass cutting fluid and grinding fluid. After long-term use, the grinding fluid becomes milky white, and the treatment method is very inefficient. And the grinding fluid needs to be replaced frequently, which is very inefficient.

Solution:

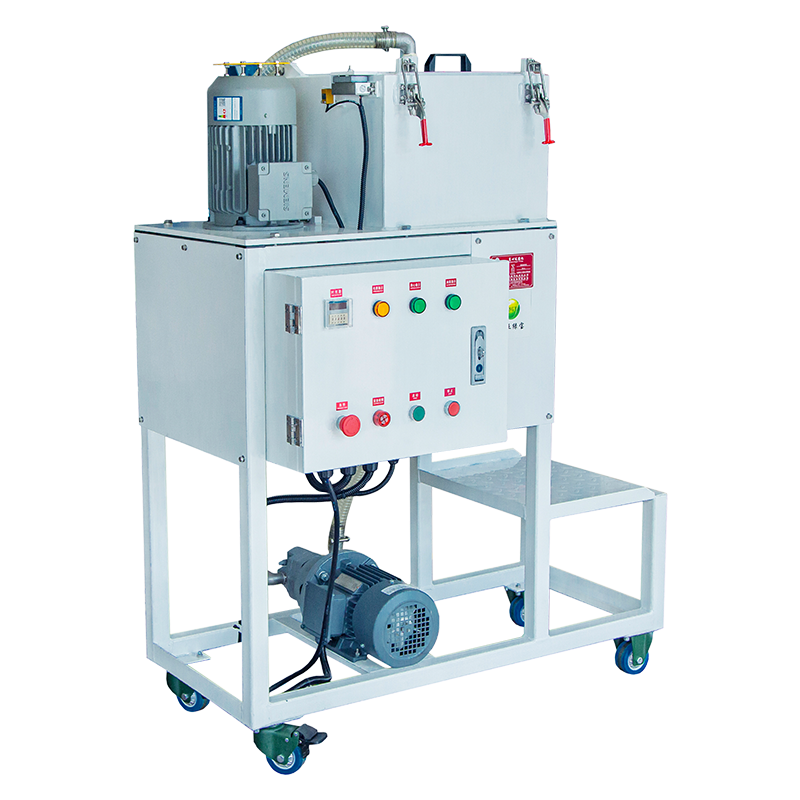

The on-site FY-1500 fully automatic slag centrifuge has a good effect after filtering. After discussing the technical solution, it is felt that centralized filtering of the grinding fluid is more efficient, and more than a dozen fully automatic slag centrifuges were purchased.

Customer Testimonials

Customer feedback: After the grinding liquid of the customer's mobile phone cover production line was filtered through a fully automatic centrifugal filter, most of the silicon powder in the grinding liquid was centrifuged out, making it very convenient to handle.

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy