CASES

Shenzhen listed enterprise glass grinding fluid filtration project

Type:

Centrifugal Filtration Of Glass Grinding Solution

Industry:

3C Industry

Customer Background

Shenzhen listed company glass grinding liquid centrifugal project. The company's technologies include cutting and grinding of ultra-thin glass substrates, polishing, tempering, vacuum magnetron sputtering coating, photolithography, graphic processing, chemical vapor deposition film formation, dry etching technology, wide viewing angle, semi-reflective and semi-transparent TFT, flexible TFT, thinning technology, CNC precision carving, laser cutting, silk screen, FOG, AFC coating, full lamination, AR coating, AF evaporation, AF spraying, AG film layer, integrated black and other technologies.

Project Introduction

Customer pain point:

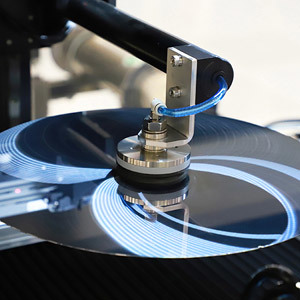

The customer's mobile phone glass grinding production line (3 workshops) produces a large amount of glass grinding liquid, which is doped with a large amount of silicon powder. After long-term use, the concentration of the grinding liquid becomes higher and higher and affects the surface finish of the workpiece, which is milky white.

Solution:

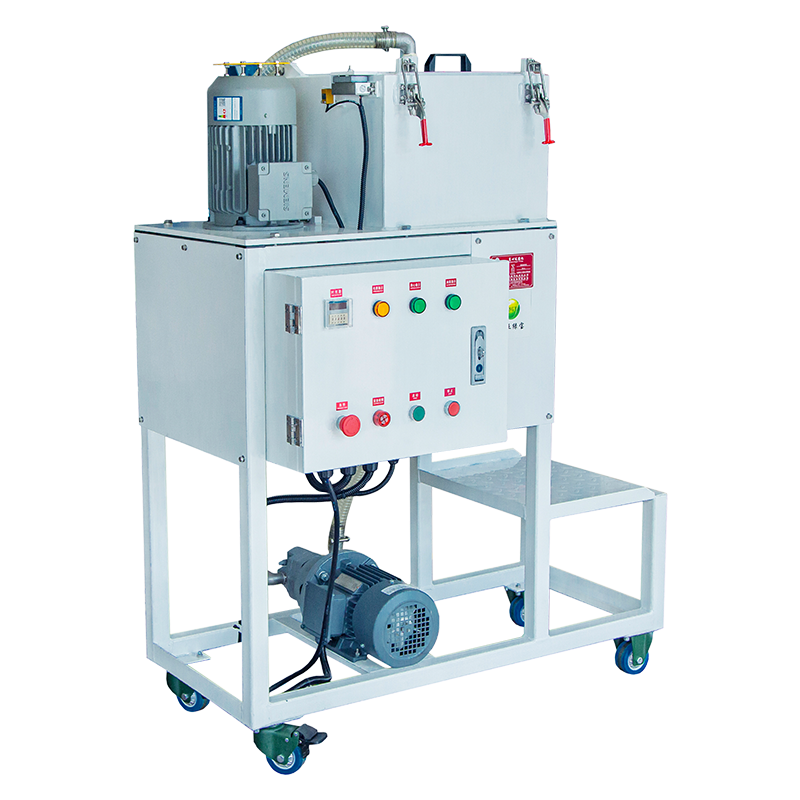

Our factory brought the fully automatic slag removal centrifugal filter equipment to the customer for preliminary testing. After a round of testing, the effect was very obvious. After centrifugal filtration of the glass grinding liquid, a large amount of silicon powder was produced and the water content was very low, achieving their expected effect.

Customer Testimonials

Customer feedback: The glass cutting fluid and grinding fluid in the workshop were previously collected and processed in a centralized manner, which was very troublesome. After using our FY-1500 equipment, the silicon powder came out of the grinding fluid, and the effect was very obvious.

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy