CASES

Case study of centrifugal slag discharge from Foshan glass edge grinding liquid

Type:

Quartz Grinding Fluid Filtration

Industry:

Semiconductor Manufacturing

Customer Background

The company was founded in 1987. Its predecessor was the design and manufacture of aluminum alloy glass doors. Since 1995, it has been specialized in the design and manufacture of shower doors. Since 2006, it has paid taxes of more than 10 million yuan for twelve consecutive years, and its employee benefits are among the best in the industry. The factory area is more than 160,000 square meters, the number of employees has reached more than 700, and the annual production and sales volume of shower doors is more than 770,000 sets. It is one of the largest shower door manufacturers in the world; its products are sold well in more than 50 countries including Europe and the United States.

Project Introduction

Customer process:

The edge grinding process of bathroom glass is roughly divided into:

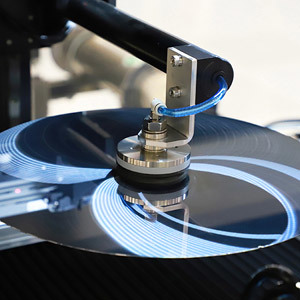

1. Rough grinding: Use a high-speed rotating rough grinding wheel to grind the glass edge to a roughly smooth surface, removing obvious burrs and uneven areas.

2. Fine grinding: Use a lower-speed rotating fine grinding wheel to further grind the rough-ground glass edge to make it smoother and more uniform.

3. Polishing: Through the combination of polishing wheel and polishing liquid, the glass edge is processed into a mirror effect to improve the overall quality of the glass.

4. Cleaning: Finally, the ground glass is cleaned to remove residual grinding impurities and polishing liquid to ensure the cleanliness and beauty of the glass.

Customer pain points:

Glass edge grinding liquid physically cools the glass in the edge grinding process, which will produce a large amount of grinding liquid and cleaning water; most companies consider increasing the water circulation volume and rely on building large pools for circulation.

The following problems will arise:

1. Large pools take up a lot of space, which is not conducive to the use of corporate space;

2. Moreover, large amounts of water are not conducive to the economy;

3. The pool will become dirty and smelly after a long period of circulation, increasing environmental pressure;

4. Manual replacement and disposal are required, which increases costs;

Customer Testimonials

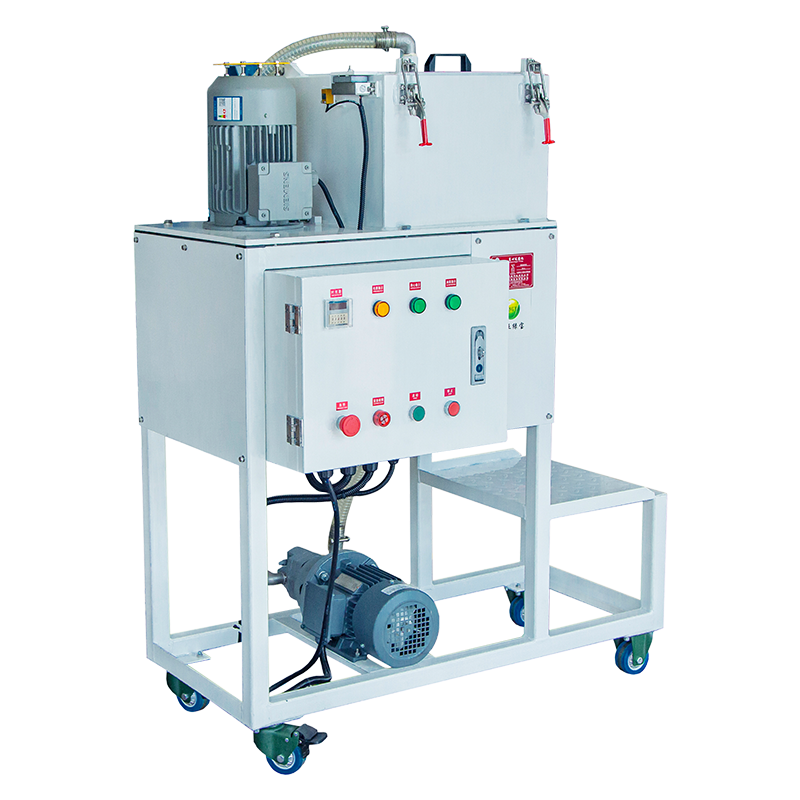

The grinding liquid mixture is pumped into the equipment. When the mixture enters the separation rotor, it is subjected to a strong centrifugal force (up to 1700 times the weight of the impurities). The mixture moves radially to the inner surface of the rotor. The flocculants, glass powder and other impurities in the mixture are compressed into a thick layer. Due to the different centrifugal forces, the filtered water flows back to the transfer tank along the reflux tank. The flocculants, glass powder and other impurities are adsorbed to the inner surface of the separator and gradually solidified. These impurities are automatically discharged through the automatic slag discharge system, thereby achieving the effect of separating impurities and water.

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy