CASES

Shaanxi Photovoltaic Silicon Grinding Fluid Filtration Project

Type:

Silicon Product Grinding Fluid Filtration

Industry:

Semiconductor Manufacturing

Customer Background

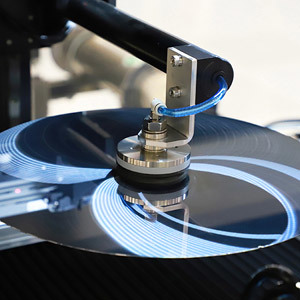

Shaanxi Photovoltaic Silicon Grinding Fluid Filtration Project: The company needs a centralized filtration system for the grinding fluid of the grinding wheels on the photovoltaic silicon product processing production line. It has 6 processing equipment on site and a 3-cubic-meter centralized water tank.

Project Introduction

Customer pain points:

It is too troublesome to clean and replace the grinding fluid regularly when it is dirty. It needs to be cleaned once a week. The original filter press takes up space and is inconvenient to clean. I want to try the centrifugal method. It does not need to be filtered and is the same as the new fluid. It can reduce the number of cleanings and reduce labor to meet the requirements.

Solution:

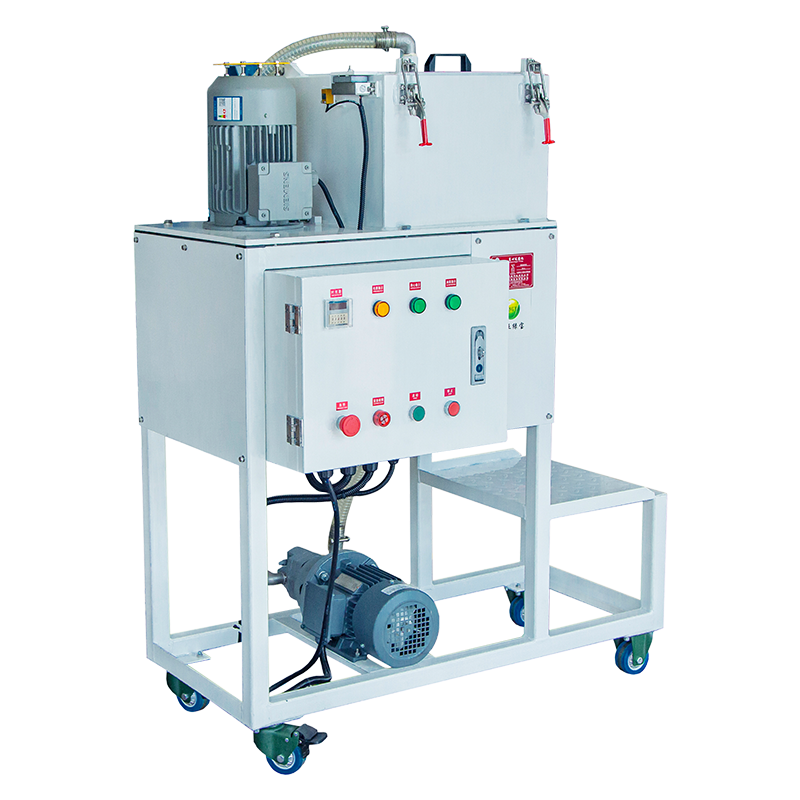

The customer sent a water sample to our company for testing and saw that the separation efficiency and final separation effect were very good. According to the amount of mud processed on site by the customer, the FY-1500 model centrifugal filter equipment was recommended. After the customer visited our company to inspect the equipment, a contract was signed.

Customer Testimonials

Customer evaluation: It reduces the time for customers to clean silica mud, improves production efficiency, and eliminates the cost of consumables such as filter presses and flocculants. In the early stage, more than 100 kilograms of silica mud are produced every day, and most of the dust in the pool can be filtered out, which is very suitable for the grinding wheel grinder processing technology.

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy