CASES

Jiangsu Steel Pipe Cleaning Saponification Liquid Filtration Scheme

Type:

Soap solution filtration

Industry:

Steel pipe processing industry

Customer Background

The customer produces more than 20,000 tons of stainless steel pipes and other products annually, with an annual output value of over RMB 300 million. Its products are sold well in more than 20 provinces and cities in China and Hong Kong, and are also exported to Japan, Singapore and other countries.

Project Introduction

Customer pain points:

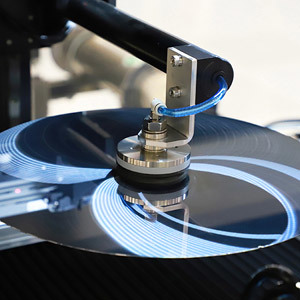

The cleaned steel pipe is lubricated with saponified liquid. After long-term use, the saponified liquid contains more impurities, and the oxide iron powder on the steel pipe falls into the saponified liquid. The centrifuge can filter out most of the impurities in the oil, reduce oil loss, and reduce the difficulty of subsequent lubrication.

Solution:

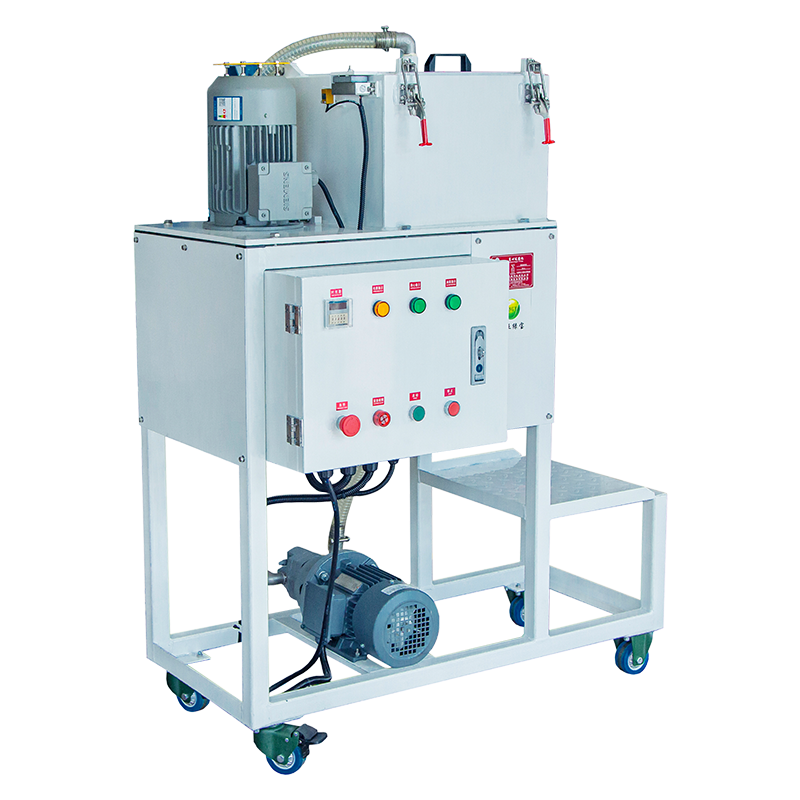

The FY1500 equipment is connected to the oil pool, which is 13 meters long and one meter wide. The saponified liquid is continuously circulated and filtered to reduce the iron powder content in the oil pool and maintain a stable oil quality.

Customer Testimonials

The oil quality is stable, the amount of iron slag is large, and the surface cleanliness of steel pipe products is improved.

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy