BLOGS

The Advantages of Centrifugal Filter Machines in Industrial Oil Filtration

2025-08-21 09:18

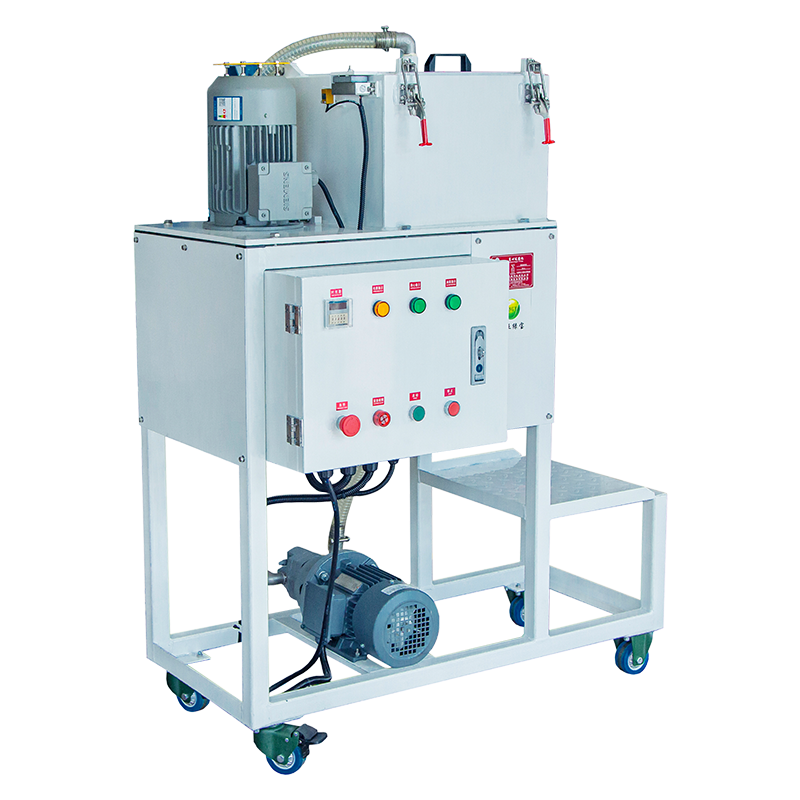

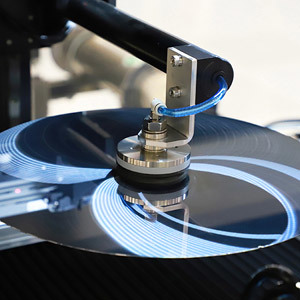

Centrifugal filter machines are revolutionizing the way industries manage their oil filtration processes. Widely used across various sectors like fasteners, wire drawing, steel pipes, and grinding, these machines provide a seamless solution for separating impurities without the need for consumable filter media. Here are some of the key advantages of using centrifugal filter machines in your industrial operations:

Efficiency and Reliability

Centrifugal filtration technology utilizes high-speed rotation to separate contaminants from oils and liquids. Unlike traditional filtration systems that rely on disposable media, centrifugal machines are built for longevity, requiring minimal maintenance. This makes them not only more cost-effective in the long run but also significantly more reliable.

Cost Savings

One of the most compelling reasons to switch to centrifugal filter machines is the cost savings. Since no consumable filter elements are needed, businesses can reduce ongoing expenses related to filter replacement and disposal. This makes the centrifugal filter a one-time investment with high returns over time.

Improved Oil Quality

By continuously filtering oils such as cold heading oil, quenching oil, and drawing lubricants, centrifugal machines help maintain the quality of the liquid. This is essential in industries that rely on the consistent performance of lubricants and cutting oils. Cleaner oil leads to longer tool life, less machine wear, and better overall product quality.

Environmentally Friendly

With no filter waste to dispose of, centrifugal filtration machines also contribute to reducing industrial waste. The continuous recycling of oil helps minimize environmental impact, aligning with sustainability goals while improving the efficiency of industrial processes.

How Centrifugal Filter Machines Improve Productivity and Cost Efficiency in Industrial Applications

2025-08-21

Why Centrifugal Filter Machines are Essential for Efficient Oil Filtration in Manufacturing

2025-08-21

The Advantages of Centrifugal Filter Machines in Industrial Oil Filtration

2025-08-21