BLOGS

How Centrifugal Filter Machines Improve Productivity and Cost Efficiency in Industrial Applications

2025-08-21 16:18

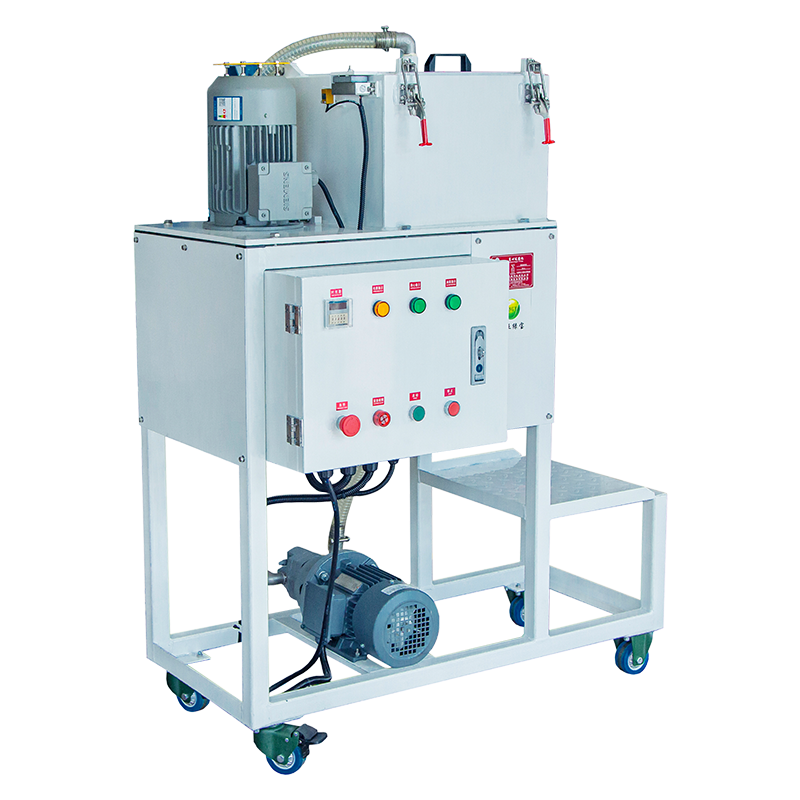

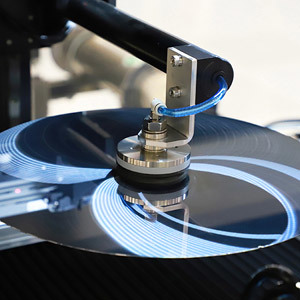

Centrifugal filter machines offer unmatched productivity and cost-efficiency in industries requiring clean, high-quality oils and fluids. From the fastener industry to wire drawing and steel pipe processing, these machines ensure that your oils remain free from contaminants, thus improving the performance and longevity of both your oils and equipment.

Self-Cleaning Process

Centrifugal filter machines are designed with a self-cleaning mechanism, meaning they don’t need manual cleaning or replacement of filter media. This reduces operational downtime and keeps the filtration system running smoothly without constant intervention. This feature is particularly beneficial for industries like steel pipe manufacturing or wire drawing, where consistent and high-quality oils are crucial for machine efficiency.

Lower Operating Costs

With the elimination of consumables, centrifugal filter machines are a smart investment for industries looking to cut costs in the long run. The maintenance-free operation and long service life make them a more economical choice compared to traditional filtration systems.

Enhanced Oil and Equipment Protection

By efficiently removing contaminants from oils such as cold heading oil and grinding fluids, centrifugal filter machines prevent sludge buildup, which can damage both machines and products. Clean oils ensure that machines run smoothly and that the final products meet the desired quality standards.

Supporting Sustainability Goals

In today’s world, many industries are focusing on sustainable practices. The centrifugal filter machine plays a key role in this effort. It minimizes waste by eliminating the need for disposable filters, thus contributing to reducing the carbon footprint of manufacturing processes.

How Centrifugal Filter Machines Improve Productivity and Cost Efficiency in Industrial Applications

2025-08-21

Why Centrifugal Filter Machines are Essential for Efficient Oil Filtration in Manufacturing

2025-08-21

The Advantages of Centrifugal Filter Machines in Industrial Oil Filtration

2025-08-21

FEEL FREE TO CONTACT US

Tel/Whatsapp:

Address: No. 189 Wangshan North Road, Kunshan City, Suzhou, Jiangsu Province

Follow Us

Copyright © 2024 Suzhou Fengyada Environmental Protection Technology Co., Ltd

Powered by www.300.cn SEO Privacy Policy