BLOGS

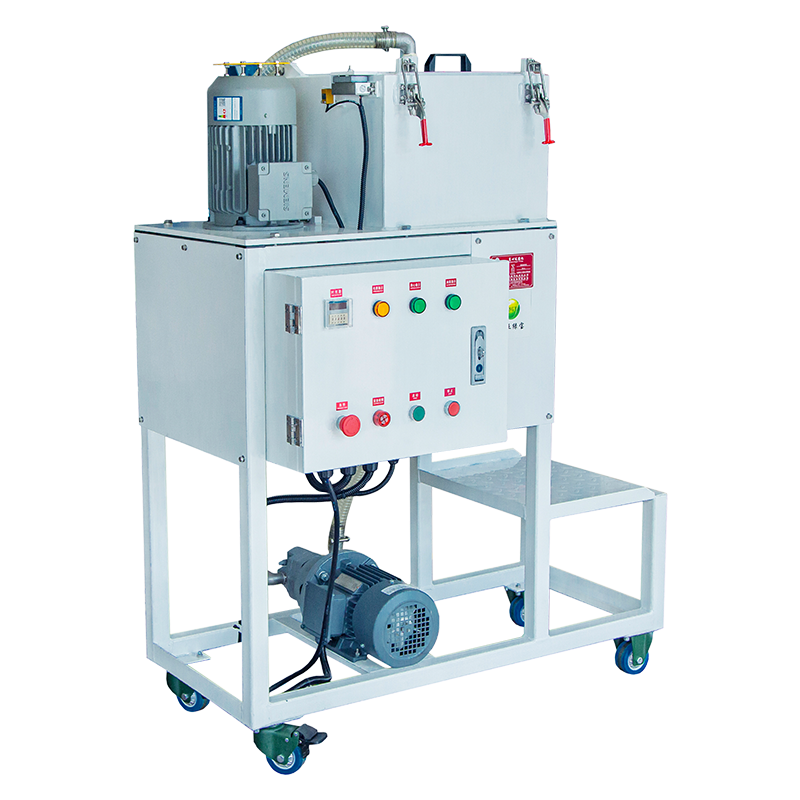

Automatic Centrifugal Oil Filter | Extend Equipment Life & Reduce Maintenance Costs

2025-08-22 13:23

Industrial processes generate a large amount of microscopic metal chips, dust, and sludge, which quickly contaminate process oils such as forming oil, tapping oil, anti-rust oil, and grinding fluids. Although these particles seem small, they are the hidden killers of equipment longevity. Once abrasive impurities circulate with oil, they increase friction, accelerate tool wear, and damage precision molds.

The automatic slag discharge centrifugal filter provides an advanced solution. By applying high-speed centrifugal separation, it efficiently removes both large debris and ultra-fine particles from oil. Unlike disposable filters that require frequent replacement, a centrifugal filter operates continuously with minimal maintenance and high efficiency.

Why Centrifugal Filtration Matters

∗ Protecting Machinery – Fine particles act like sandpaper inside equipment, damaging molds, spindles, and pumps. Removing them ensures smooth operation.

∗ Reducing Downtime – Less wear means fewer breakdowns, less unplanned maintenance, and higher productivity.

∗ Cost Savings – Clean oil can be reused for longer periods, cutting oil purchase costs and reducing waste disposal expenses.

∗ Sustainable Production – Recycling oils aligns with green manufacturing practices, lowering environmental impact.

Real-World Industrial Applications

∗ Fastener Production – Cold heading oil remains free of sludge, protecting punches and dies.

∗ Wire Drawing – Drawing oil for copper and aluminum wires retains stability, reducing wire snapping and improving quality.

∗ Steel Pipe Processing – Lubricants in pipe drawing and rolling operate cleanly, preventing scratches and ensuring smooth surfaces.

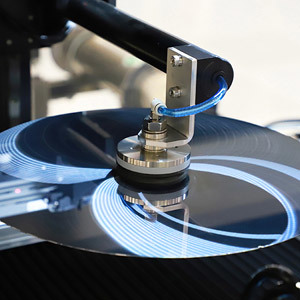

∗ Grinding Industry – Grinding fluids filtered by centrifugal machines minimize abrasive particle circulation, improving surface finish and tool life.

By integrating centrifugal filtration technology, companies achieve a triple advantage: reduced wear, lower costs, and longer oil life. It is an essential step toward efficient, reliable, and sustainable production.

Centrifugal Oil Filtration System | Cleaner Oil, Less Wear, Higher Productivity

2025-08-22

Automatic Centrifugal Oil Filter | Extend Equipment Life & Reduce Maintenance Costs

2025-08-22

Centrifugal Filter Machine for Fine Particle Removal | Reduce Wear & Improve Efficiency

2025-08-22