BLOGS

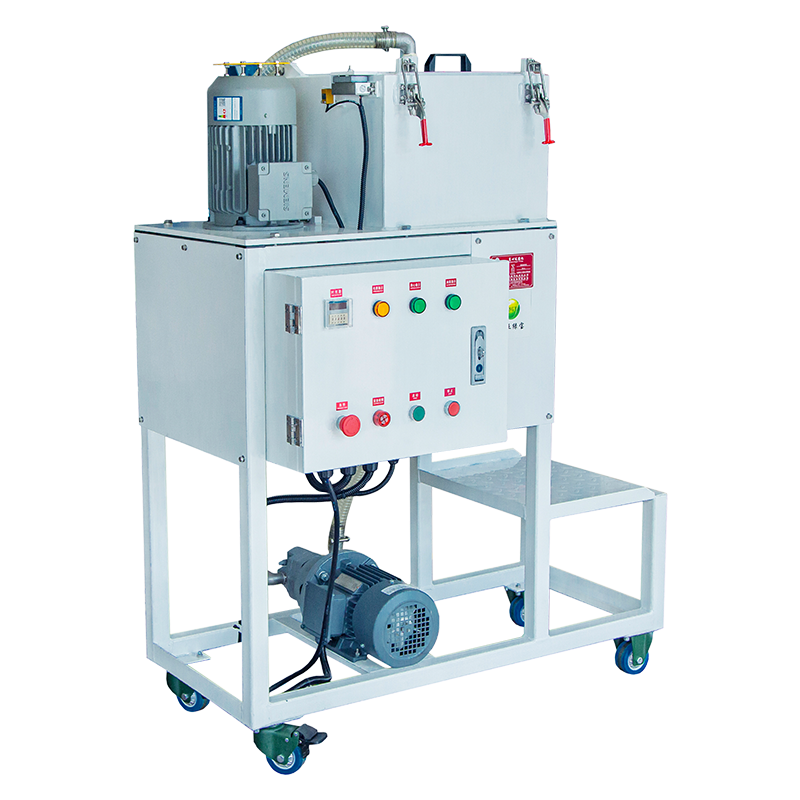

Centrifugal Oil Filtration System | Cleaner Oil, Less Wear, Higher Productivity

2025-08-22 14:58

Contaminated oils are a silent threat in industrial production. Even when oils look clean, they may contain microscopic particles that continuously erode machinery, shorten tool life, and cause unexpected failures. Industries such as fasteners, wire and cable, steel pipe, and grinding require a reliable filtration solution that goes beyond surface cleaning.

The automatic centrifugal oil filter stands out as a superior choice. By harnessing centrifugal force, it spins out particles as small as a few microns, separating them from oils like cold heading oil, forming oil, quenching oil, drawing oil, and grinding fluid. This ensures that the oil used in production is consistently clean and stable.

Key Advantages

∗ Micron-Level Filtration – Removes invisible contaminants that traditional filters often miss.

∗ Less Wear, Longer Tool Life – Cleaner oil protects molds, dies, grinding wheels, and machinery components.

∗ Stable Production Quality – Consistent lubrication leads to smoother processes, better product finish, and fewer rejects.

∗ Reduced Operational Costs – Extended oil usage and reduced tool consumption translate into direct cost savings.

Industry Case Examples

∗ Fasteners – Quenching oil remains free of impurities, preventing surface defects and ensuring product reliability.

∗ Wire and Cable – Drawing oils stay clean, reducing surface scratches and improving tensile strength.

∗ Steel Pipes – Lubricants in drawing and rolling stay stable, extending the lifespan of rollers and mandrels.

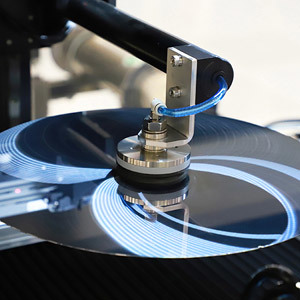

∗ Grinding and Polishing – Grinding fluids filtered by centrifugal machines keep abrasive particles away, reducing wheel wear and improving precision.

For manufacturers seeking to improve both efficiency and sustainability, centrifugal oil filters are no longer optional—they are a necessity. They not only extend equipment and oil life but also create long-term value by reducing costs and ensuring consistent product quality.

Centrifugal Oil Filtration System | Cleaner Oil, Less Wear, Higher Productivity

2025-08-22

Automatic Centrifugal Oil Filter | Extend Equipment Life & Reduce Maintenance Costs

2025-08-22

Centrifugal Filter Machine for Fine Particle Removal | Reduce Wear & Improve Efficiency

2025-08-22