BLOGS

How to deal with dirty cold heading oil

2023-10-10 10:29

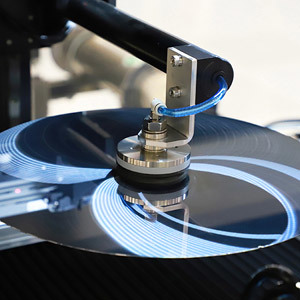

Common problem: Cold heading engine oil pollutes quickly during use, and the types of pollutants include mechanical impurities, oxide skin, sludge, aluminum powder, iron powder, carbon black, and so on. Due to the presence of pollutants, the performance of cold heading engine oil decreases. Changing the oil not only increases the production cost of the enterprise, but also cannot fundamentally solve the problem of rapid dirtiness of the oil even after changing the oil.

※ Resulting in: dirty oil, short oil change cycle, and increased oil costs

1、 The problems that customers expect to solve

Filter the mechanical impurities, oxide scale, sludge, aluminum powder, iron powder, carbon black, and other substances generated during the production of cold heading oil, making the oil cleaner and improving the lubrication and cooling performance of the cold heading oil

※ Extend the service life of cold heading oil and save oil costs without frequent oil changes

2、 Solution

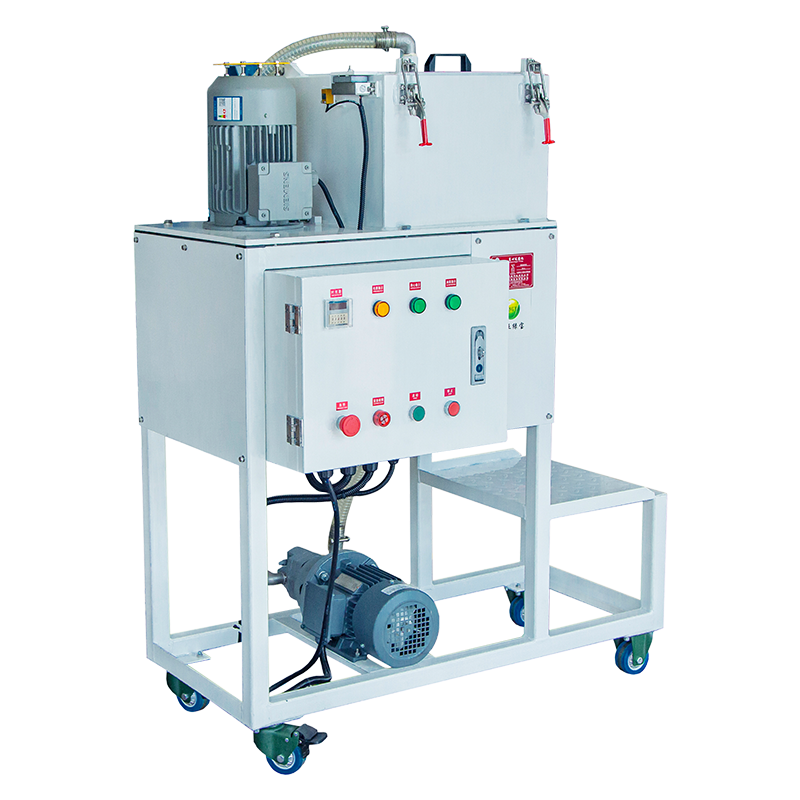

The high-speed centrifuge is used to filter iron filings and impurities in the cold heading oil. The fully automatic slag discharge centrifugal filter is based on the principle of centrifugal force to remove pollutants from the lubricating oil. The hydraulic driving force is used to increase the pressure inside the hub, and the pressure is instantly released through a double spray rotor inside the centrifuge, driving the inner rotor to rotate at high speed and remove impurities.

3、 Characteristics of high-speed centrifuge

※ Variable frequency design, allowing for free adjustment of speed to change the centrifugal force G value

※ Oil sludge with low oil content does not require further oil removal treatment

Separate impurities of 5 μ m or more in the oil

※ Fully automatic control, automatic slag removal, no need for personnel on duty

※ No filter or filter replacement, no consumables

※ The equipment has a small footprint and can be operated in a mobile manner

※ Installation plans can be designed based on the actual working conditions of the customer's site

5、 Produce effect

Extend the service life of oil/fluid by 3-5 times

※ Improve product quality and reduce product wear and tear

※ Reduce production equipment maintenance costs and minimize waste oil generation

Optimize production processes and improve working environments

How Centrifugal Filter Machines Improve Productivity and Cost Efficiency in Industrial Applications

2025-08-21

Why Centrifugal Filter Machines are Essential for Efficient Oil Filtration in Manufacturing

2025-08-21

The Advantages of Centrifugal Filter Machines in Industrial Oil Filtration

2025-08-21